LIQUID NITROGEN ALUMINIUM EXTRUSION PROCESS

Increased aluminium extrusion speed of at least 20% and improved surface quality

WHAT IS ALUMINIUM EXTRUSION WITH LIQUID NITROGEN?

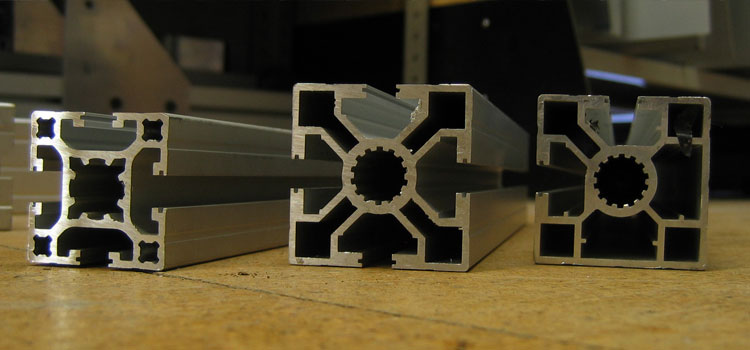

Aluminium profile sections are produced by pressing hot aluminium billets through the die opening of a ram extruder. The temperature of the preheated die is increased by mechanical friction and forming work and this increase in temperature causes the surface of the extruded aluminium to oxidize which affects the surface quality. A further increase in temperature can also result in mechanical defects of the extruded sections and reduce the die lifetime. Therefore, there is a need to control the temperature. The solution is to inject liquid nitrogen through the grooves machined in the extrusion die during the extrusion process. It reduces the temperature of the extruded aluminium and die as well as displacing the air around the hot extruded aluminium to avoid the formation of oxides. This results in a shiny profile surface and a better quality product.

We offer a full turnkey solution including product supply; equipment consultation and supply; equipment training; and feasibility studies and cost/benefit analysis.